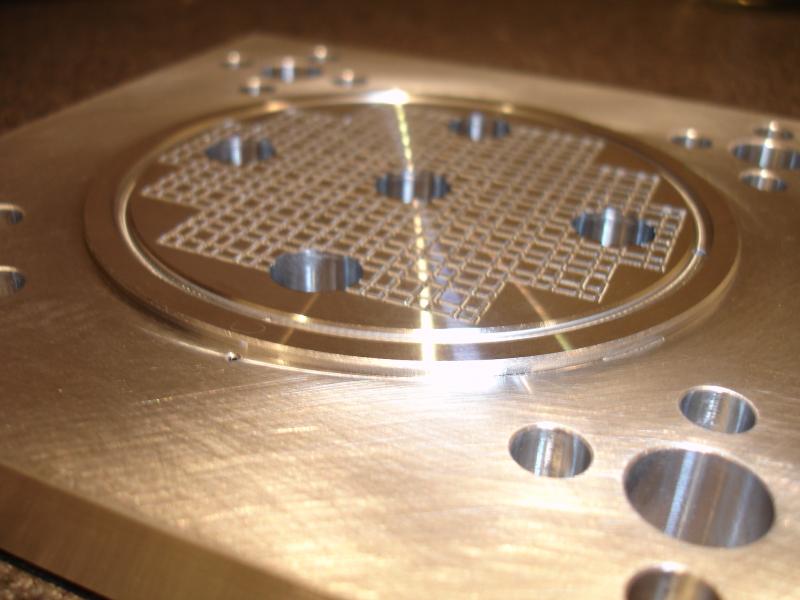

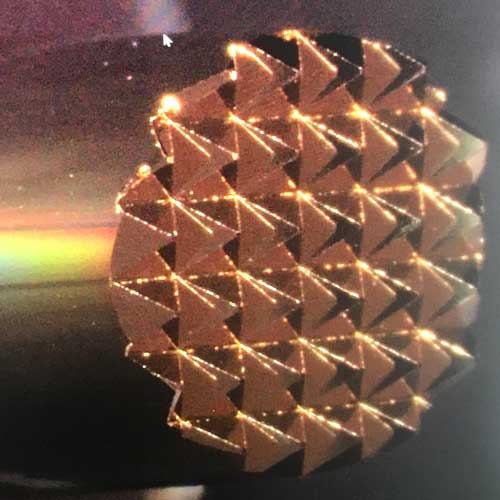

CNC or computer numerical control is a manufacturing process that is focused on precision, consistency, flexibility, and cost savings. It offers many distinct advantages for technology and optics companies who need to develop and prototype quickly. Unlike many diamond machining suppliers, Nanophorm has In-House CNC machining capability that allows us to produce optics blanks and tooling quickly. We can also produce parts that don’t require diamond turning, allowing us to be a “one-stop” supplier for your precision assembly.

Nanophorm specializes in using computer software to control the movement of machining and milling tools in order to shape and cut raw materials into finished parts or products. We are adept at working with complex design files and translating them into a products and tools for our customers.

In addition to multi-axis machining and milling, we also offer plating and specialty capabilities including: