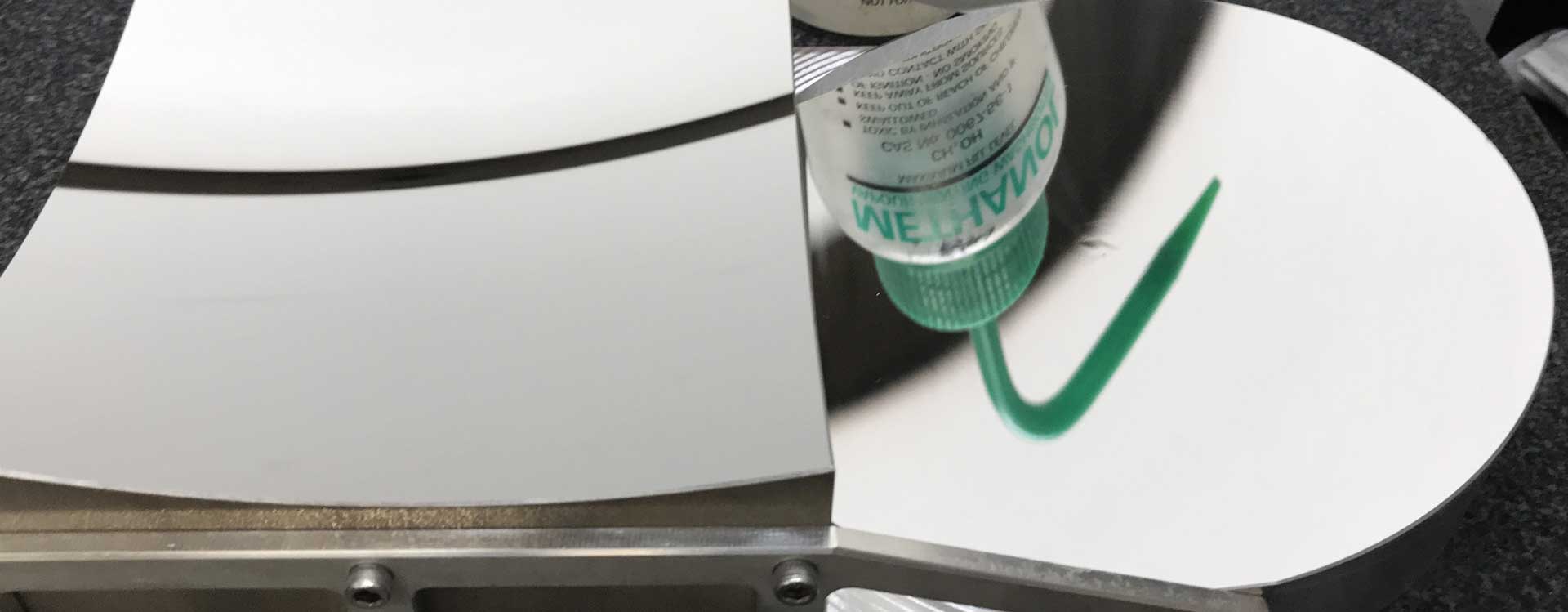

Nanophorm’s precision engineering experience shows that we have the knowledge, skills, and equipment necessary to produce high-quality components under diverse conditions and with an array of materials. We are very familiar with the various machining processes and technologies such as diamond turning, milling, and grinding. We’re able to work with a wide range of materials commonly used throughout aerospace, medical, defense, automotive, telecommunications, and consumer electronics.

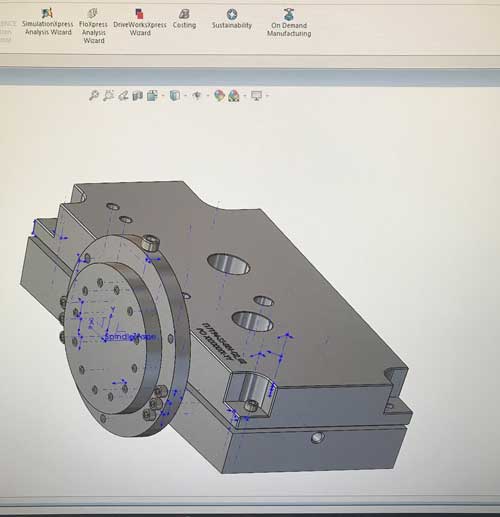

Nanophorm has in-house design and manufacturing engineering capability, whether you are looking for a complete design or some friendly advice on improving your product, we are here to help.

We are Pro/ENGINEER, SolidWorks, and Zemax capable.

Our precision engineering experience demonstrates that we have a strong quality control program in place. A key part of our engineering expertise is our ability to measure and inspect optical components to ensure they meet the required tolerances and specifications. We also have experience with various testing and validation processes, such as interferometry and spectroscopy.