Nanophorm is nimble, vertically integrated, extremely well-equipped, and staffed by passionate engineers with real-world product development experience. This means you get better results, faster.

Your most complex prototyping and production problems are our focus. We partner with you early, providing valuable manufacturability advice. We then turn to our in-house, vertically integrated facility to rapidly complete your project. Our expertise includes CNC machining and grinding, diamond turning, CNC lapping and polishing, heat-treat, plating, and optical coating. This is all backed by NIST-traceable metrology. With Nanophorm, you get your components faster and hence your product to market faster.

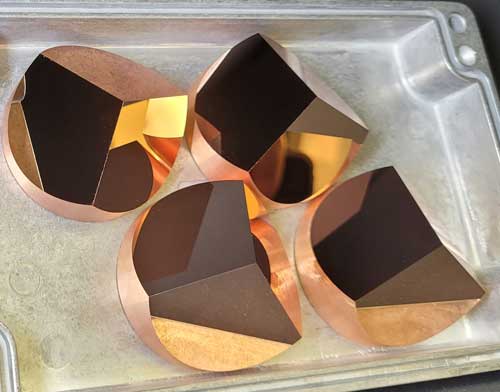

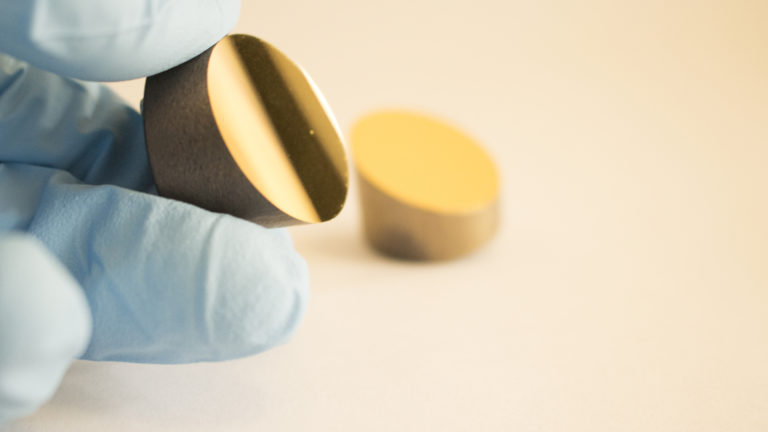

Nanophorm has years of experience delivering high-precision optics to our customers. Mirrors, lenses, arrays of almost any conceivable geometry including:

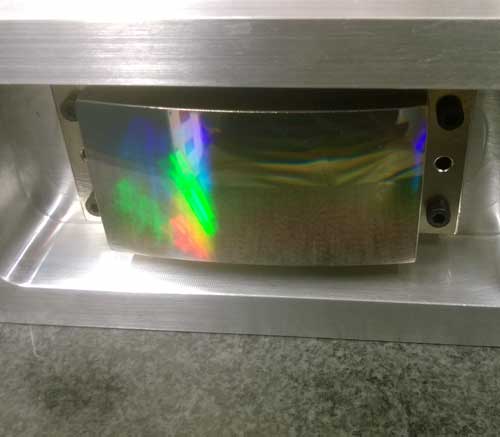

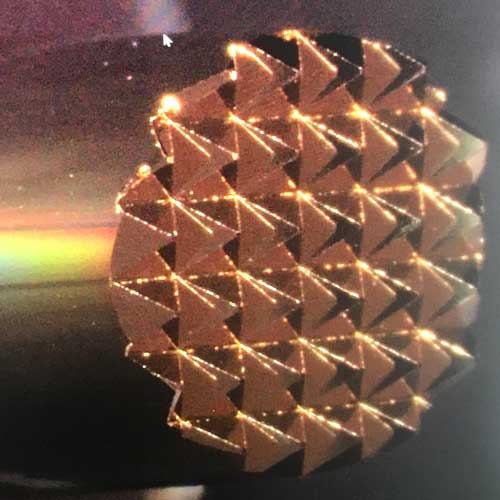

Diffractive, micro-structured, and TIR (total internal reflection) optics separate light into its component wavelengths for analysis, improved imaging, and to help identify surface structure.

We produce:

CNC and precision manufacturing systems are ideal for building the forms and molds needed to manufacture using injection and compression molded components, such as those used in a variety of industries. We have experience with :

Precision engineering is essential in the production of optics and photonics products, such as lenses, mirrors, prisms, and filters, where even small deviations from the desired specifications can impact the performance of the final product. We help manufacture:

We manufacture and help structure rigs and platforms for complex beam steering prisms and other optical systems which require precision and materials experience including: